The idea

In industrial rope access, technicians rely on two anchored ropes for safety and mobility. After each operation, these ropes — often exceeding 100 meters — must be retrieved and packed for transport and inspection.

Until now, this process has been entirely manual — physically demanding, time-consuming, and inefficient.

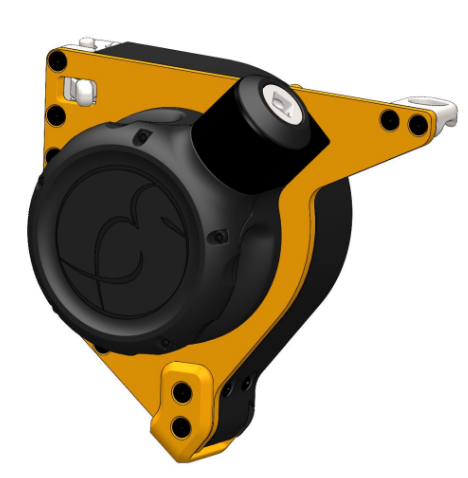

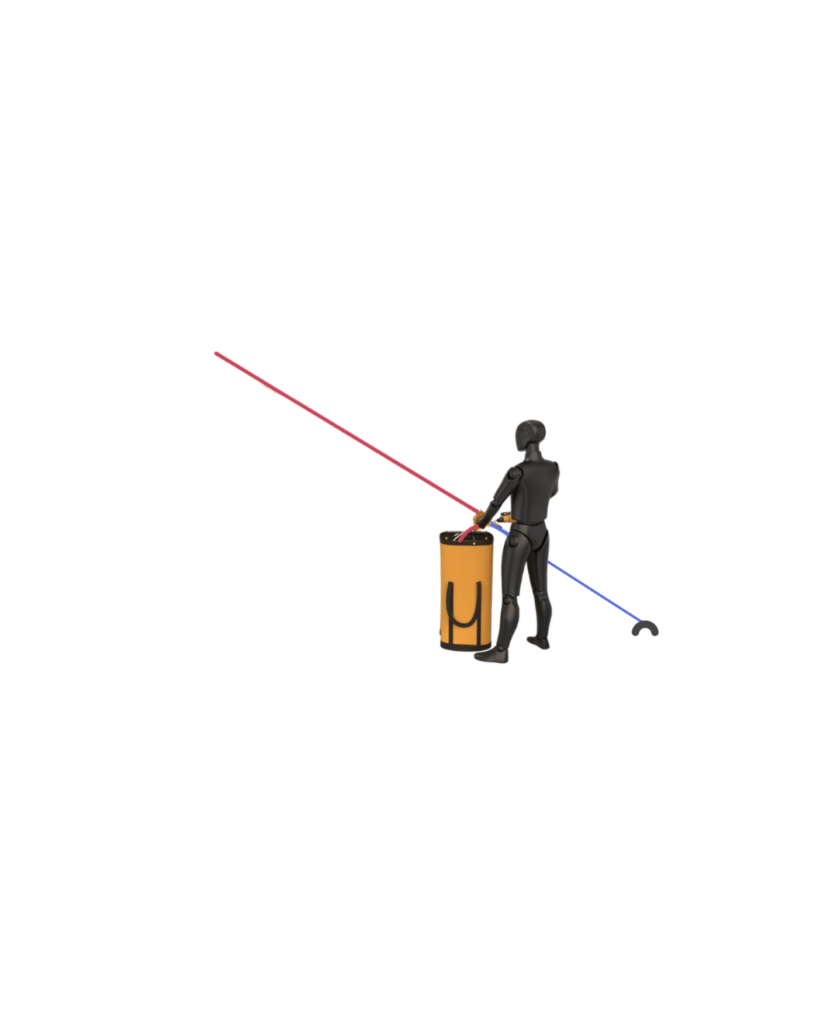

To change that, we developed the RopeDriver: a lightweight, robust, and highly portable device powered by any standard cordless drill. It enables powered hoisting and simultaneous rope storage, either as a stand-alone unit or extended with the BagFrame, which keeps the rope bag upright and aligned for smooth operation.

This new, continuous way of working proved so efficient that we gave it a name: SpinStow™ — a single, fluid motion that lets one technician hoist and store rope at the same time.

The result is a new level of efficiency, safety, and ease in industrial rope access.

The RopeDriver

The RopeDriver™ features the SpinStow™ method — a unique approach that lets one technician hoist and store rope simultaneously.

With a Working Load Limit (WLL) of 35 kg, it is designed and configured to SpinStow climbing ropes efficiently on any wind turbine.

During operation, the RopeDriver is held in the left hand, while the drill, connected via a socket, is operated with the right hand, keeping both hands safely engaged.

Inside, a bevel gear transmission converts drill speed into torque and drives the coil. Rope installation takes only seconds — simply wind the rope once around the coil and you’re ready to operate.

A slip clutch, based on a pre-tensioned disc spring set to the WLL, automatically disengages if the load becomes too high, ensuring safety.

The result is a major ergonomic improvement and significant time savings — an advantage that grows even greater during offshore maintenance, where efficiency directly impacts cost and scheduling.

The rope entry port untwists and guides the incoming rope smoothly onto the coil, with a locking element to prevent back-sliding.

An adjustable pressure element pushes the rope deeper into the V-shaped coil for improved grip and accommodates different rope diameters.

The rope exit port releases the rope cleanly and directs it outward in the preferred direction.

Built-in safety systems include:

– Automatic direction control to prevent unintended reverse drive.

– An integrated slip clutch that disengages when the WLL is exceeded.

– A variable-pressure system that adapts to different rope types.

Once installed, the rope cannot slip back unless manually released via the rope clamp.

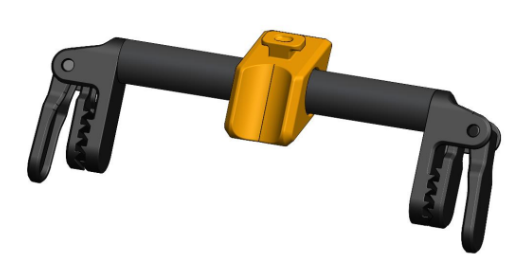

The BagFrame

Different rope bags behave differently in use.

Smaller bags usually stay open, allowing the RopeDriver to feed the rope directly inside.

Larger bags — often used for long ropes — tend to collapse when not filled, and the rope itself can behave springily under tension.

The BagFrame solves this by attaching directly to the RopeDriver. It keeps the rope bag upright, stable, and properly aligned, allowing the RopeDriver to connect closely and guide the rope smoothly into the bag.

Different rope bags — one smart connection.

The Spin&Stow™ Method

Hoisting rope is influenced not only by length but also by friction from ground contact, edges, direction changes, wind, and humidity. These factors add resistance to every meter lifted.

Traditionally, technicians must pull this weight manually — a physically demanding, two-person task.

The RopeDriver, with its 45 kg Recommended Load Limit, takes over this heavy work.

The combination of RopeDriver, drill, BagFrame, and rope bag forms a dynamic and innovative setup that enables SpinStow™ — powered hoisting and simultaneous rope storage.

It transforms a strenuous manual routine into a fast, controlled, one-person operation, reducing fatigue, saving time, and improving safety across every maintenance cycle.

SpinStowTM

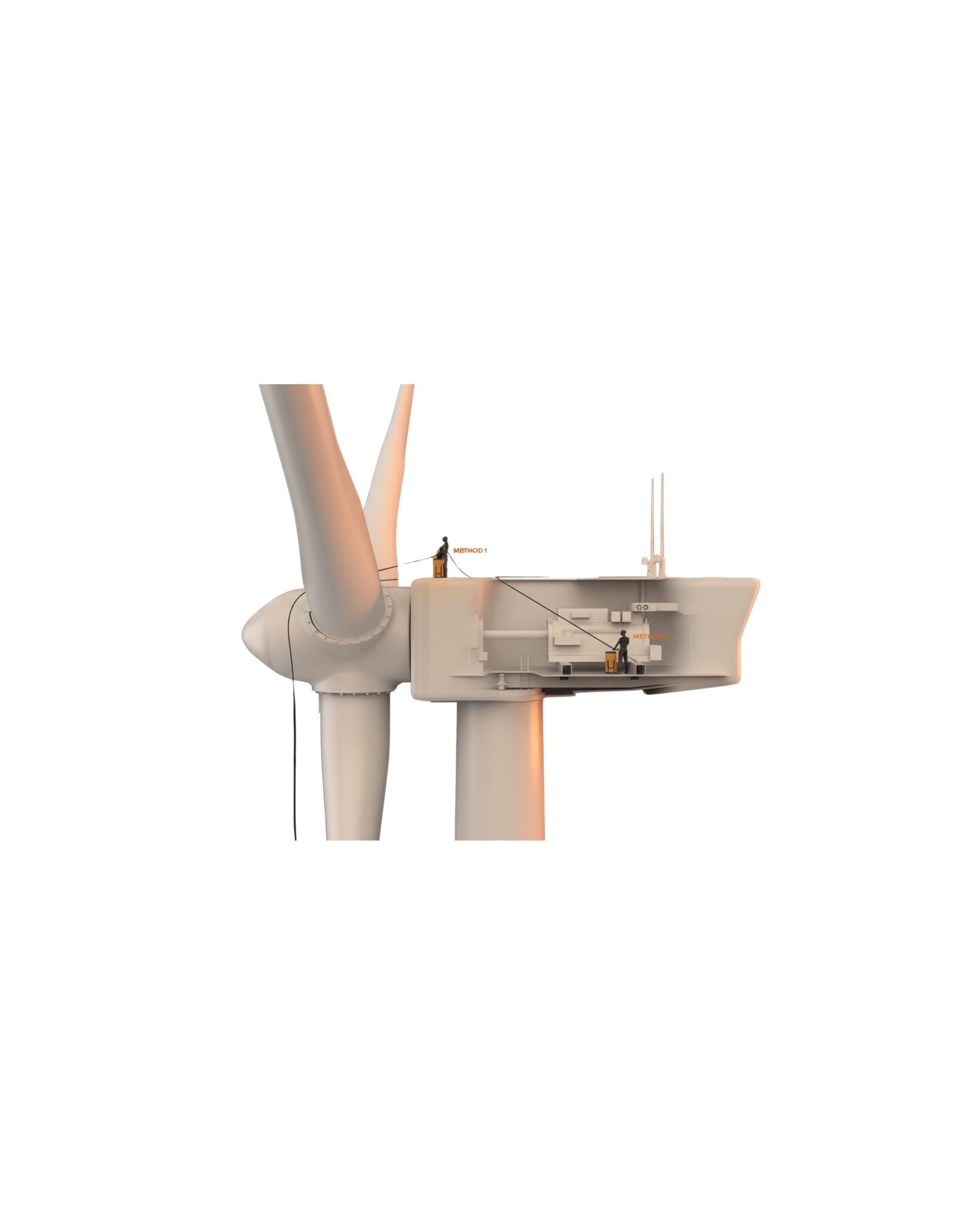

from the harness D-ring

In this working method the user works closer to the edge, which typically means lower total drag on the rope.

To prevent the user being pulled off balance—or into a fall—by rope weight, the user must be on a work-restraint line attached to a secure anchor.

The harness is in the load path between the RopeDriver and the ground-based restraint. As an example, with 200 m of rope and assuming one friction point giving a friction factor = 1.2, the load on the user is approximately 20 kg.

SpinStowTM

from within the nacelle

Spin&Stow from inside the nacelle improves technician comfort and safety, but typically increases rope friction.

Our manual describes a simple setup that keeps the technician out of the load path, so no hoisting load rests on the user.

Safety note: If the RopeDriver’s slip clutch engages, the applied load has exceeded its Working Load Limit (WLL). This usually indicates too much rope length and/or a high friction factor in the current work setup. Reduce rope length, minimize ground/edge contact, or re-route to lower friction before continuing.

Discover more about the design, innovation, and sustainability behind RopeSpinner.